Why is Fiber Cement Cladding the Smartest Choice for Building on Guyana's Soft Soil?

Building heavy concrete structures on the swampy soil of Georgetown or the East Coast requires expensive piling and massive foundations to prevent sinking. Smart developers are switching to Lightweight Dry Construction, using Fiber Cement Siding over a Steel Frame to reduce building weight by 70% while achieving a stunning, modern aesthetic.

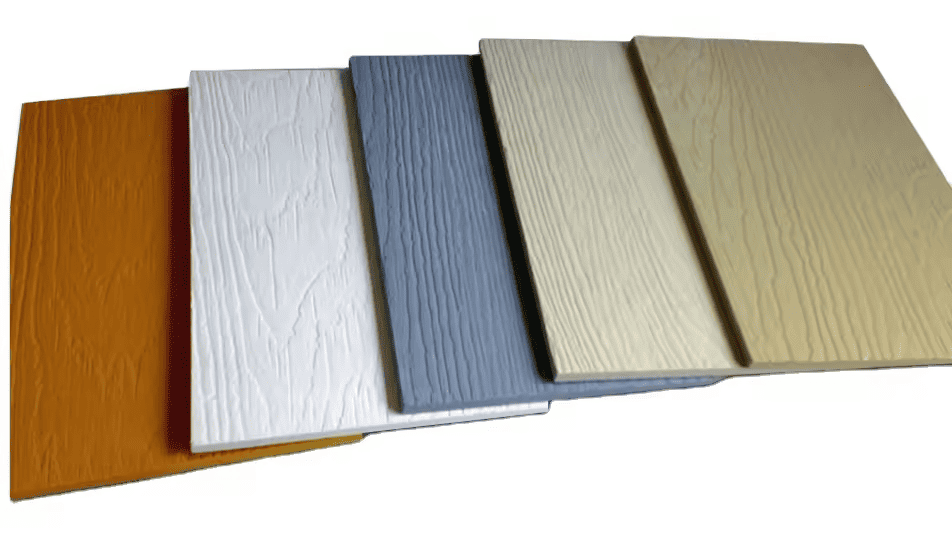

Fiber Cement Siding Planks (Wood Grain) offer the luxurious look of American timber homes without the weight of concrete or the rotting risk of wood. When installed on our Structural Galvanized Steel Keels, this system creates a high-strength, low-weight building envelope that saves you thousands of dollars on foundation concrete while strictly meeting ASTM fire and safety codes.

I often talk to engineers in Guyana who struggle with the water table. You dig two feet, and you hit water. Pouring a heavy concrete foundation in these conditions is a nightmare. The solution isn't to build a stronger foundation; it is to build a lighter house.

How Can "Lightweight Construction" Save Your Foundation Budget?

A traditional concrete block wall weighs heavily on the soil, requiring deep piles to avoid cracking. A Cement Board & Steel system is a fraction of the weight, allowing for simpler, cheaper foundations without compromising structural integrity.

By replacing blockwork with Fiber Cement Boards (exterior) and Gypsum Boards (interior) mounted on Galvanized Steel Studs, you reduce the "Dead Load" of the building. This is critical for second-story additions on older houses or new builds in marshy areas, ensuring your investment stands straight while your neighbor's heavy concrete wall starts to crack and settle.

Let's look at the engineering reality.

- Concrete Block Wall: ~250kg per square meter.

- Fiber Cement + Steel Wall: ~45kg per square meter.

That is a huge difference. If you are adding a top floor to a house in Queenstown or Kitty, can the old columns support concrete blocks? Probably not. But they can definitely support our Cement Board System.

| Feature | Concrete Block Wall | TRUSUS Cement Board System | Benefit for Guyana Soil |

|---|---|---|---|

| Total Weight | Very Heavy | Ultra Lightweight | Reduces foundation sinking |

| Foundation Cost | High (Needs piles) | Low (Raft/Pad) | Saves cash on concrete |

| Install Speed | Slow (Curing time) | Fast (Dry construction) | Finishes weeks earlier |

| Aesthetics | Plain / Plastered | Wood Grain Texture | High-end "Villa" look |

| Durability | Cracks with settling | Flexible & Tough | Handles movement better |

How Do You Achieve the "American Villa" Look Without the Rot?

Everyone loves the look of "Clapboard" or "Ship-lap" houses seen in North America, but importing pine timber to Guyana is a recipe for termite disaster.

Our Wood-Grain Fiber Cement Siding is molded with a realistic timber texture but is made of Portland cement and cellulose. It paints beautifully, never twists in the sun, and is completely fire-resistant. You get the curb appeal of a luxury wooden villa with the permanence of stone.

The "Hidden" System: To make this look perfect, you cannot just nail it up. You need our Full Facade System:

- The Frame: Use our 0.8mm - 1.2mm Structural Studs. Do not use thin drywall studs!

- The Barrier: Wrap the frame in Tyvek (breathable membrane) which we can supply.

- The Board: Screw on the Cement Siding Planks using our specialized Ceramic Coated Screws (so you don't see rust trails down your white wall).

- The Corner: Use our pre-fabricated Cement Corners for a sharp finish.

This is how you build a house that looks like a million dollars but costs less than a concrete bunker.

Conclusion

Don't fight the soft soil with heavy concrete. Float above it with Fiber Cement Siding and Steel Framing. It is lighter, faster, and more beautiful.